Fabric Deep DiveKnit FabricTechnical KnitsTextile Glossary

2026年1月25日

Bow, Skew & Twist: A Technical Q&A for Textile Quality Control

For textile engineers, QC teams, and apparel manufacturers, misalignment defects like bow, skew, and twist are frequent sources of production delays, cost overruns, and customer disputes.

For textile engineers, QC teams, and apparel manufacturers, misalignment defects like bow, skew, and twist are frequent sources of production delays, cost overruns, and customer disputes. This technical Q&A breaks down key definitions, testing standards, and real-world impacts to help you avoid common pitfalls.

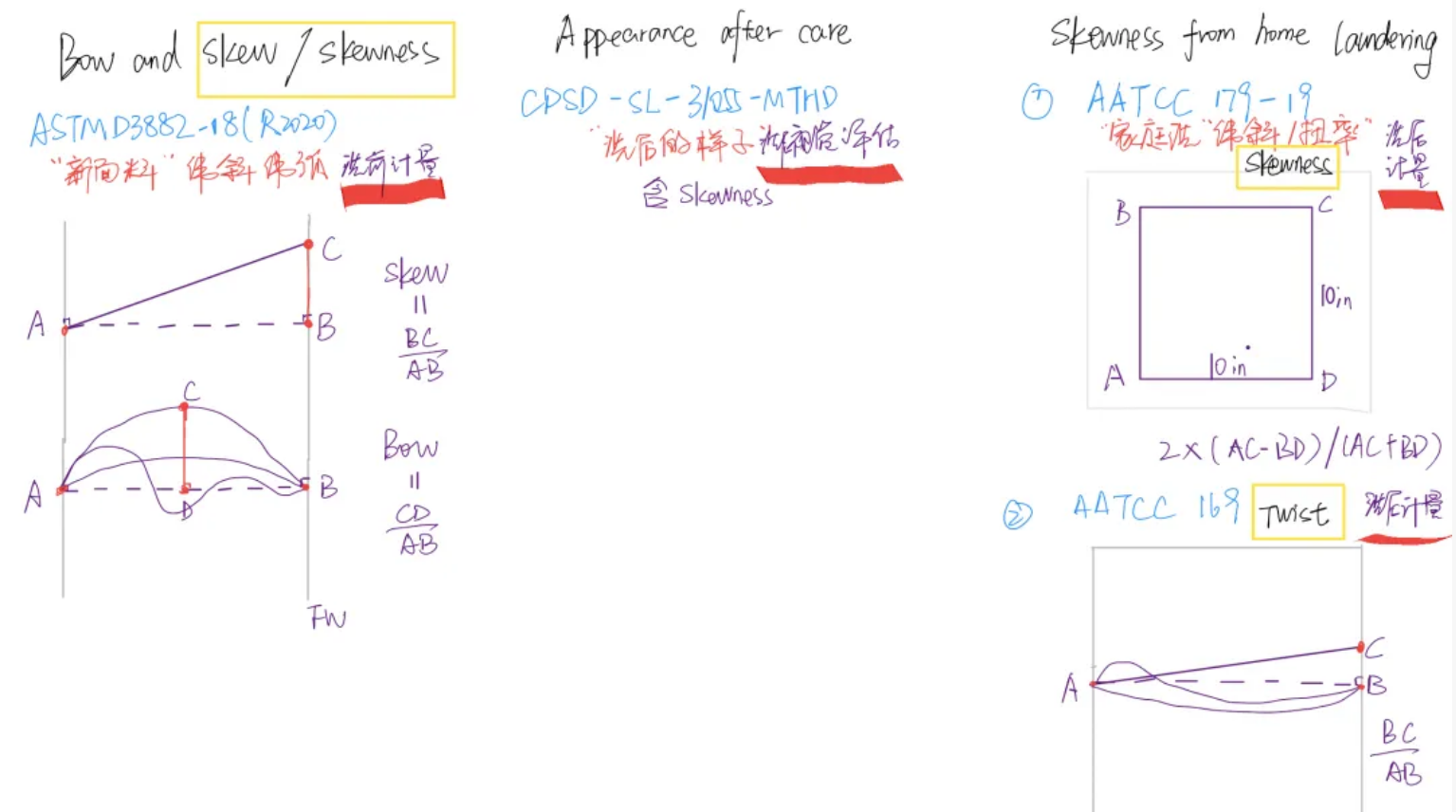

Q1: What’s the difference between Bow, Skew, and Twist?

These three defects represent distinct forms of fabric misalignment, each measured by specific standards:

- Bow : Curved deviation of the weft yarn from a straight, perpendicular line to the warp. Measured via ASTM D3882 (pre-wash static test) by calculating the maximum distance between the curved weft and the reference line.

- Skew : Linear, angular deviation of the weft yarn from the warp’s perpendicular axis. Tested via ASTM D3882 (pre-wash) and AATCC 179 (post-wash home laundering), with results reported as a percentage of fabric width.

- Twist : Three-dimensional spiral distortion of the fabric, common in stretch knits (e.g., spandex jersey). Evaluated via AATCC 169, which measures spiral deformation after washing.

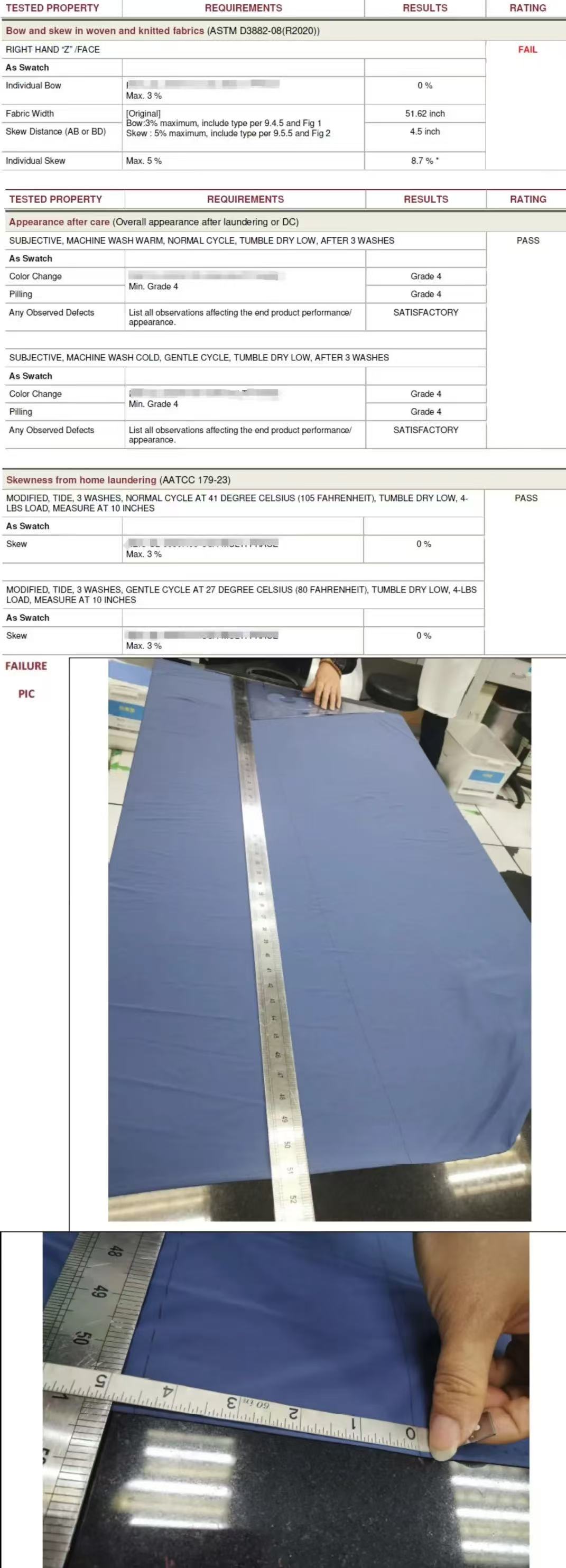

Q2: Why is “skew pass/fail” ambiguous? Why must we distinguish pre-wash vs. post-wash performance?

A vague “skew pass” can lead to supply chain disputes because pre-wash and post-wash testing serve different critical purposes:

- Pre-wash skew (ASTM D3882): Ensures cutting accuracy (e.g., stripe alignment for shirts, pattern matching for dresses).

- Post-wash deformation (AATCC 179/169, CPSD-SL-3105): Validates garment stability after consumer laundering, focusing on real-world wear appearance.

To eliminate ambiguity, always specify three key details:

- Test Standard: e.g., ASTM D3882-08, AATCC 179-19

- Test Condition: Pre-wash or post-wash (including wash cycles)

- Tolerance: e.g., “Pre-wash skew ≤5%, post-wash twist ≤3%”

Q3: Do only lightweight fabrics need pre-wash ASTM D3882 testing? Can heavyweight fabrics skip this in bulk production?

All fabrics—lightweight or heavyweight—require pre-wash bow/skew testing, but:

- Heavyweight fabrics (e.g., canvas, denim) have tighter yarn cohesion, so skew risk is lower, and some clients may accept relaxed tolerances.

- Skipping pre-wash testing for bulk orders is only justifiable if:

- The client explicitly approves post-shrinkage remediation, or

- The order is low-value, prioritizing cost over precision.

Q4: Do test reports distinguish between positive and negative skew directions?

Yes. Skew direction is referenced to the warp:

- Positive (+): Weft shifts right relative to the warp.

- Negative (-): Weft shifts left relative to the warp.

Formal reports (e.g., SGS) will note direction, but tolerance evaluations typically use absolute values—unless the client specifies directional requirements (e.g., for symmetric patterns).

Q5: If a fabric has multiple bow defects across its width, how is the final bow rate calculated?

The maximum deviation value across the full width is used to calculate the bow rate. This ensures the worst-case defect is captured, as even localized bow can disrupt pattern alignment during cutting.

Q6: Why do stretch fabrics need controlled pre-wash skew, while non-spandex jersey requires skew setting and bias cutting?

This is rooted in managing internal fabric stress and performance:

- Stretch fabrics (with spandex): A small, intentional pre-wash skew balances spandex tension during heat setting. Eliminating skew entirely (0% tolerance) risks:

- Loose, baggy fabric from insufficient spandex tension.

- Uneven post-wash shrinkage, causing “wavy edges” or distortion.

- Cutting room defects (e.g., warped pattern pieces).

- Non-spandex jersey: Skew setting and bias cutting release weaving-induced internal stress, improving:

- Garment drape and fit (via 45° stretch).

- Resistance to post-cut curling (e.g., neckline roll).

- Comfort by reducing rigid, straight-grain tension.

Q7: What are the tangible costs of ignoring excessive pre-wash skew for apparel factories?

A skew rate of 8.7% (as seen in the test report example) directly impacts production efficiency and profitability:

- Cutting efficiency: 1.5m width fabric loses 10cm per meter, reducing material utilization by 7%.

- Labor costs: Mirroring patterns or skew cutting increases layout time by 30%.

- Quality risks: Unremediated skew leads to 20% higher customer complaints (e.g., twisted seams, misaligned stripes).

Pre-shrinking can mitigate some issues, but it introduces new risks (e.g., color bleeding, over-shrinkage). The most cost-effective solution is to control skew at the fabric mill during heat setting.

Let’s Discuss

Fellow textile professionals—what’s your biggest challenge in managing bow/skew/twist? Have you encountered disputes over ambiguous “skew pass” language? Share your troubleshooting tips below!