Fabric Deep DiveTextile Glossary

2026年2月20日

Flammability vs. Flame Resistant (FR) Fabrics: 12 Critical Questions Every Fabric & Apparel Professional Must Understand

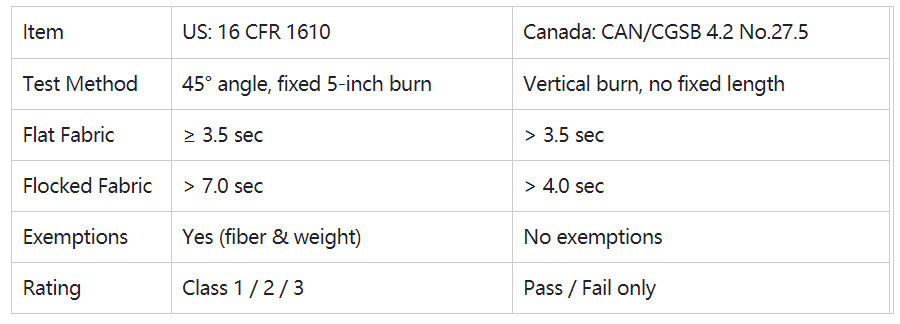

Q1: Are flammability and flame resistance the same thing? A: No. They are completely different concepts. One-sentence summary: Flammability = entry-level safety pass; Flame resistance = advanced per

Q1: Are flammability and flame resistance the same thing?

A: No. They are completely different concepts.

One-sentence summary:Flammability = entry-level safety pass; Flame resistance = advanced performance.

Q2: If a fabric passes FR testing, does it mean it won’t burn at all?

A: No. No textile is completely non-combustible.Flame resistant fabrics are designed to:

- Be difficult to ignite

- Self-extinguish when removed from the flame

- Not spread fire or produce molten dripping

They may still burn under extreme or sustained heat, but burn extremely slowly and greatly reduce burn injury risk.

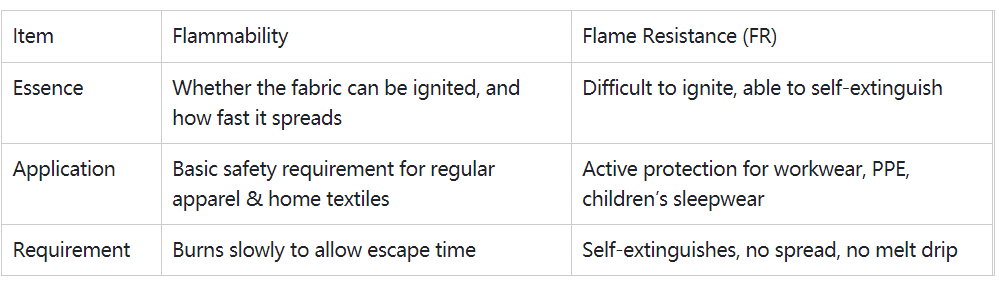

Q3: What is US Standard Class 1? How to pass?

A: Under 16 CFR 1610 (US flammability standard), fabrics are classified into 3 levels.Class 1 is the ONLY acceptable grade for apparel.

Q4: Which fabrics are exempt from US flammability testing?

A: Exempt if meeting either condition:

a. Fiber Exemption100% or blends only of:Acrylic, Modacrylic, Nylon, Olefin, Polyester, Wool.⚠ If any other fiber (e.g., 5% spandex) is added → NO exemption.

b. Weight Exemption (flat fabrics only)Weight ≥ 88.2 g/m² (≈ 2.6 oz/yd²)Flocked/napped fabrics CANNOT use weight exemption.

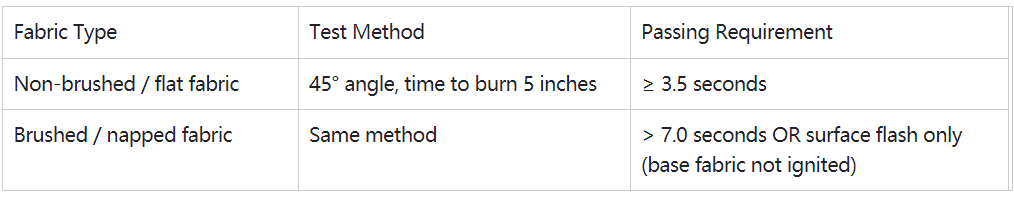

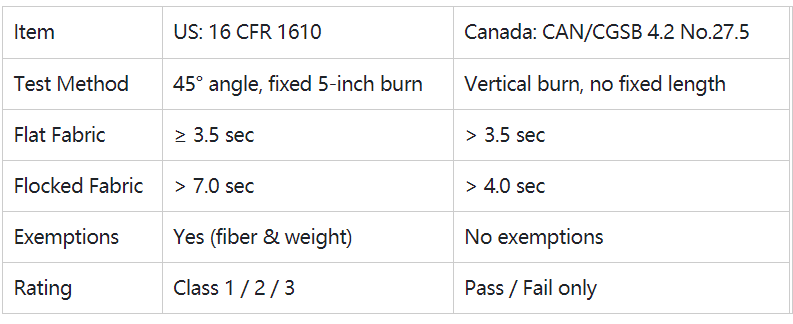

Q5: What is the difference between US and Canadian flammability standards?

Summary: US is structured and rule-based; Canada is result-based.

Q6: Why are flocked/napped fabrics stricter than flat fabrics?

A: Structure increases risk.Napped, fleece, velour fabrics have larger surface area and trap more oxygen → ignite easier and burn faster.Therefore, all countries apply stricter requirements.

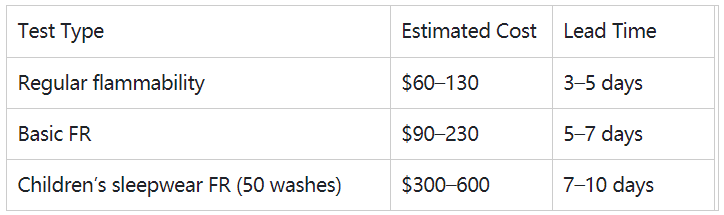

Q7: Testing cost & lead time?

Q8: The biggest mistake fabric suppliers make in flammability testing?

A: Not confirming end-use before testing.

- Adult apparel: 16 CFR 1610 Class 1

- Children’s apparel (non-sleepwear): same standard, but stricter performance

- Children’s sleepwear: mandatory dedicated FR standard (16 CFR 1615/1616)— CANNOT use regular flammability test.

Wrong test = customs detention, recall, fines.

Q9: Will softeners affect flammability or FR performance?

A: YES — they can directly cause failure.Silicones, softeners, water-repellent finishes can:

- Make fabrics easier to burn

- Neutralize flame retardant effects

Always use FR-compatible auxiliaries and re-test after finishing.

Q10: When to do flammability test? When to do FR test?

A:

- Flammability test: All regular apparel (unless exempt) — basic safety entry.

- FR test: Only required in 3 cases:

- Product claims “flame resistant”

- Protective wear (workwear, welding, firefighting)

- Legally required items (children’s sleepwear, public textiles)

Q11: Why do global brands focus on US & Canadian standards?

A: They set the global benchmark:

- Most mature and strict regulations

- Largest consumer markets

- Highest penalties for non-compliance

- Many markets (EU, AU, NZ) adopt similar frameworks

Q12: Can children’s sleepwear use regular flammability testing?

A: NO. Never.Children’s sleepwear is high-risk and requires dedicated FR testing (e.g., 16 CFR 1615/1616, EN 14878).It must withstand 50+ washes, no melt drip, no flame spread.Regular flammability reports are invalid and will result in seizure.

Q13: When a client says “I want flame resistant fabric”, what should I do first?

A: Confirm 3 critical details to avoid wrong testing and wasted cost:

- Target market (US, EU, Canada, Japan — standards are not interchangeable)

- Exact standard number (e.g., 16 CFR 1615, EN 14878)

- Wash durability (how many washes? Typically 50 washes for sleepwear)

Only then select the correct fabric and arrange the right test to meet compliance.