Industry InsightsKnit FabricTechnical KnitsTextile Glossary

2026年1月25日

Mid-Layer Fleece Showdown: Primaloft® Active Evolve vs. Polartec® Alpha Direct vs. Teijin® Octa

For outdoor apparel engineers, brand buyers, and material innovators, the mid-layer fleece is the unsung hero of thermal regulation.

For outdoor apparel engineers, brand buyers, and material innovators, the mid-layer fleece is the unsung hero of thermal regulation.

Three technologies—Primaloft® Active Evolve, Polartec® Alpha Direct, and Teijin® Octa—have redefined performance standards by balancing lightweight design, dynamic heat management, and sustainability.

Here’s a technical breakdown of their core innovations and the industry trends they’re driving.

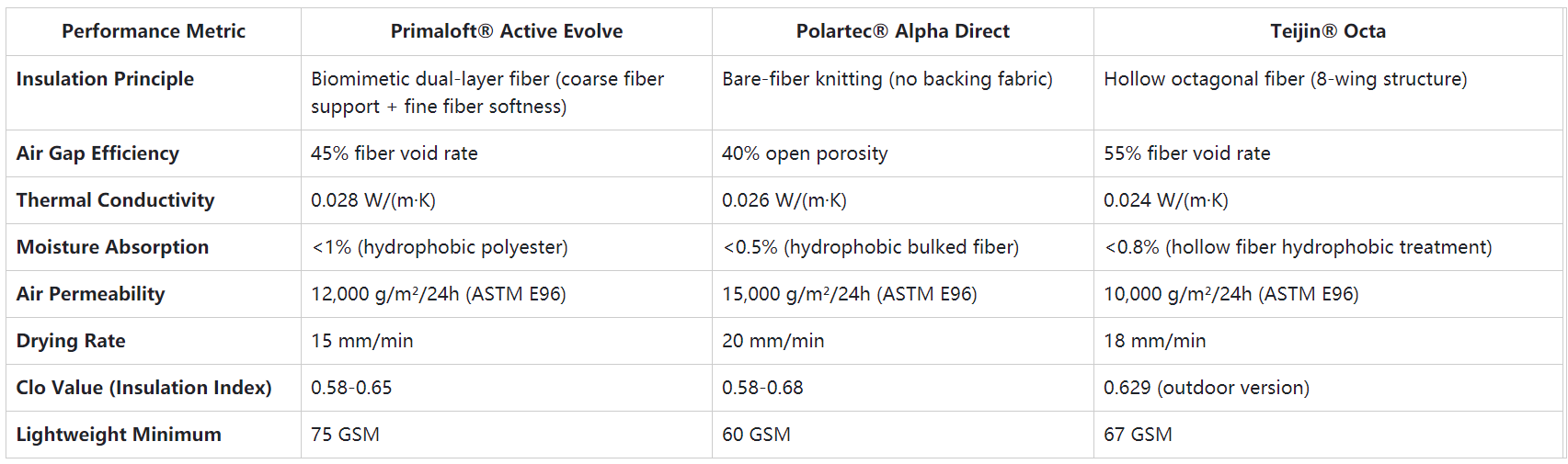

Core Technology & Performance Comparison

Each fabric uses a distinct structural design to achieve thermal efficiency, breathability, and durability:

Key Innovations:

- Primaloft® Active Evolve: Inspired by animal fur, its dual-layer fiber system (20-30μm coarse fibers for air retention, 10-15μm fine fibers for softness) delivers 45% air void efficiency. The 100% polyester material is GRS-certified and chemically recyclable via Primaloft’s closed-loop technology, which converts old garments into virgin-quality fiber with 80% regeneration efficiency.

- Polartec® Alpha Direct: A game-changer for high-output activities, its “bare-fiber” construction eliminates the backing fabric, boosting breathability by 30% and reducing weight by 20% vs. traditional Polartec Alpha. The 15μm bulked fibers create open pores for rapid moisture escape, making it ideal for marathon running and alpine hiking.

- Teijin® Octa: Its hollow octagonal fiber cross-section increases perimeter by 35% and void rate to 55%, achieving the highest Clo value (0.629) among the three. With a 0.8dtex monofilament fineness, it delivers a softness rating of 150mN—32% softer than conventional fleece—while maintaining durability.

Industry Trends Shaping the Future

The mid-layer fleece sector is evolving rapidly, driven by three key forces:

- Intelligent Thermal Regulation:

- Polartec® has partnered with Norrona to integrate AI-optimized fiber alignment into its Lyngen series, enabling dynamic temperature adjustment between -15°C and +10°C. Its Power Air line uses 3D knitting to create surface air channels, boosting heat dissipation by 40% while retaining a 0.65 Clo value.

- Circular Economy & Bio-Based Materials:

- Primaloft®’s collaboration with Emerson has achieved 80% fiber regeneration, reducing CO₂ emissions by 6 tons per ton of recycled material. Teijin is developing a sugarcane-based bio-Octa fiber, targeting 50% lower carbon footprint by 2026.

- 3D Structural Innovation:

- Teijin’s 3D spiral fiber (DNA-inspired design) aims to increase void rate to 60% and push Clo values above 0.7 by 2027. Polartec’s I-Beam technology uses laser-cut fiber structures to enhance tear resistance by 30%, now featured in Arc’teryx’s Kyanite AR jacket.

Market & Brand Strategy Insights

- Global Growth: The mid-layer fleece market is projected to reach $1.035 billion by 2030 (CAGR 5.2%). In China, the fleece hoodie market alone is expected to exceed ¥120 billion by 2025, with Z-gen consumers driving >50% growth in lightweight fleece sales during 2024’s Tmall Double 11.

- Competitive Barriers: For textile professionals, mastering Octa’s fiber modification, Alpha Direct’s backing-free knitting equipment, and Active Evolve’s chemical recycling processes will be critical to staying ahead in the next 3-5 years.

- Scene-Specific Solutions: Brands are increasingly segmenting products by use case—e.g., Polartec Alpha Direct for trail running, Teijin Octa for urban commuting, and Primaloft Active Evolve for backcountry hiking—to meet niche consumer needs.